-

10+

Years of research

-

900x

Faster diagnostics

-

10x

Efficiency

-

85-100%

Less CO2 emissions

CeLLife Cell Pro solution

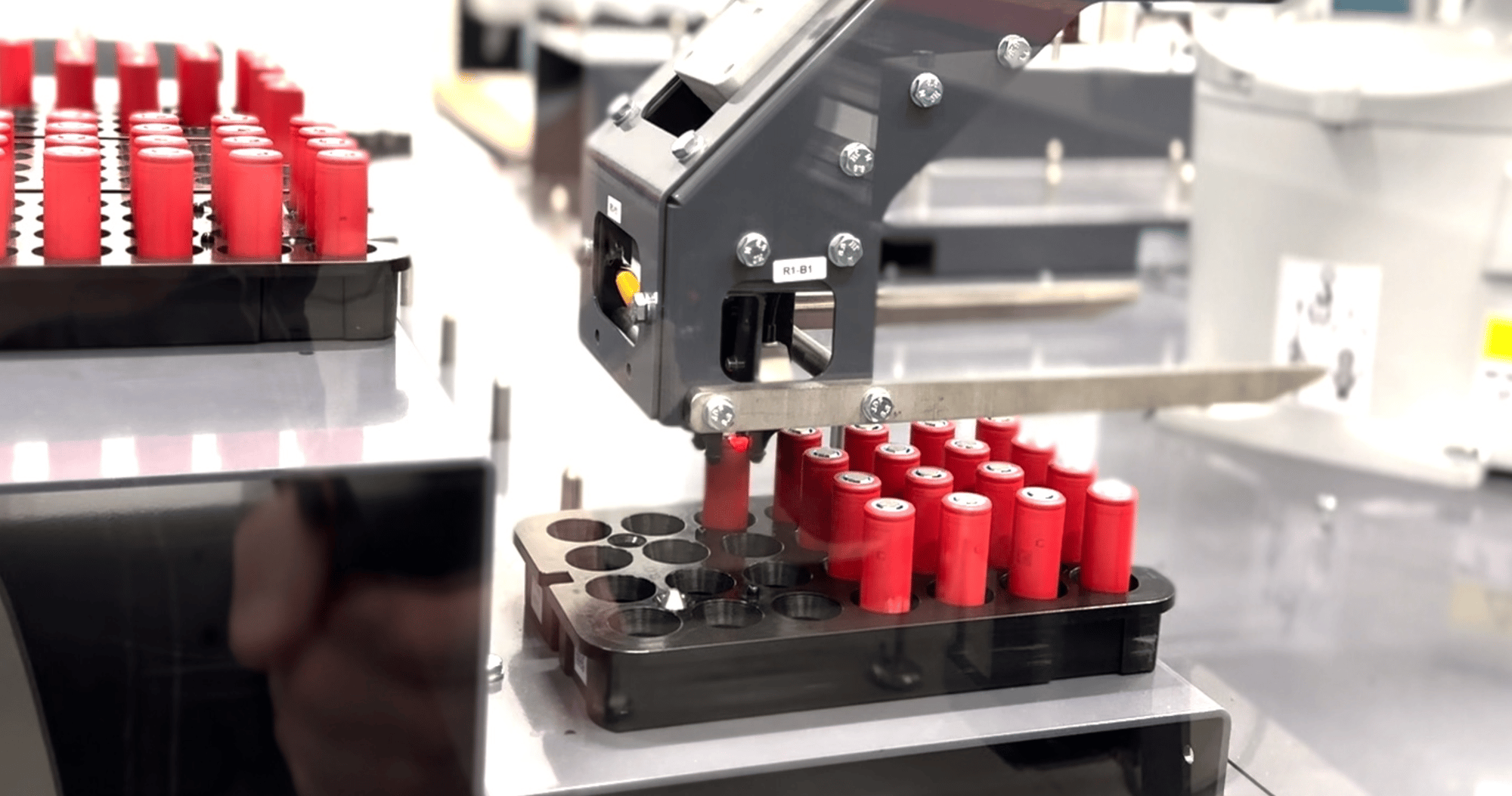

Purpose-built for cell manufacturing and module assembly quality control,

Our solution enables real-time evaluation of every single cell on the production line

Seamless integration – Fast & Accurate –Traceability

CeLLife Cell Pro

Fully automated diagnostic solution purpose-built for seamless integration, consistency, traceability, and zero-defect delivery

Overview

Fully automated Quality Control

for Battery Manufacturing

- CeLLife Cell Pro solution leverages EFP™ technology to deliver fast, accurate, and easy-to-integrate battery diagnostics

- Compact set-up, seamless integration directly onto production line

- Deliver diagnostics results in seconds

Key features

100% testing coverage without

slowing down throughput

- Full test time take approximately 5 seconds

- Provides near real-time, AI-powered diagnostics

- Leverages EFP™ technology for super fast, accurate, and traceable diagnostics results

Key benefits

CeLLife Cell Pro enables

a closed-loop feedback system

- In-Process Quality Control (IPQC) and End-of-Line (EoL) testing for cell manufacturing

- Incoming cell entry checks and post-assembly validation for module assembly

- Unlock deeper insights, enabling instant defect detection and process optimization

OUR CLIENT TESTIMONIALS

" Cellife's solution has significantly enhanced our battery measurement capabilities, providing the precision and efficiency that align with our customers' operational needs. We are highly impressed with both the solution and their expertise. Intek is proud to collaborate with Cellife, integrating cutting-edge technology that serves as the missing link—completing our turn-key lines with state-of-the-art solutions. This partnership further strengthens our customers' quality and control capabilities, enabling them to deliver even better products."

Looking for

the technical details?

Gain early insights, optimize and solve issues quickly

2,000 data points in under 2 seconds covering quality, performance, health, lifetime prediction, safety, and electrical properties are stored in the cloud, together with optimal measurement parameters and learning algorithms.

Bring Electrical Fingerprint (EFP™) into production and scale industrially

Our solution is industrially scalable and can cover your high-volume production on a daily basis fitting any chemistry, form factor, voltage or power. CeLLife Cell Pro solution helps to ensure quality in every stage of battery manufacturing production

Enhance efficiency with the fastest and the most accurate solution

Easily install CeLLife hardware and get diagnostics in 2-5 seconds. Each measurement with 2,000 datapoints contributes to making smart predictions and insightful dashboards, helping to trace root causes.

Applications

How it works

1. Implement CeLLife solution

Together with our experts, we help you install CeLLife hardware to cover your entire production. Unlike traditional methods, such as CT scans, you can measure your entire production – and still save in costs and time.

2. Gain insights, get an overview and trace issues

Get comprehensive analytics for every produced cell, including detecting mechanical and electrochemical defects and quality variation. Optimize your processes through AI-driven root-cause analysis and fine-tuning of parameters.

.png?width=2000&height=1053&name=Untitled-7%20(2).png)

3. Guarantee superior quality with intelligent analytics

Store data in the cloud service for traceability and analysis development. Our intelligent analytics will ensure you constantly learn and are able to provide safe, well performing, quality cells and batteries.