Palmiresíduos, Portugal’s leading battery recycling operator, has revolutionized its EV battery testing process with CeLLife Lite. By adopting CeLLife Lite solution - AI-powered EV battery module diagnostics, the company can now evaluate 100% of incoming EV modules in seconds, eliminating testing bottlenecks, maximizing second-life recovery, and advancing sustainable battery recycling. This success highlights how innovative EV battery testing solutions are enabling faster, more reliable, and more sustainable industrial-scale operations.

The Problem: Lengthy Testing Time Diagnostics That Slowed Down Operation

Testing electric vehicle battery modules is a critical step before they can be reused, resold, or recycled. However, traditional processes for battery module diagnostics are critically slow, taking hours or even days per module, and require expert interpretation. These limitations created bottlenecks for Palmiresíduos, delaying decisions around reuse and recycling, and constraining the company’s ability to scale operations.

And CeLLife Lite solution has the answer for this tricky puzzle

The Solution: Precision comes with Speed and Scalability

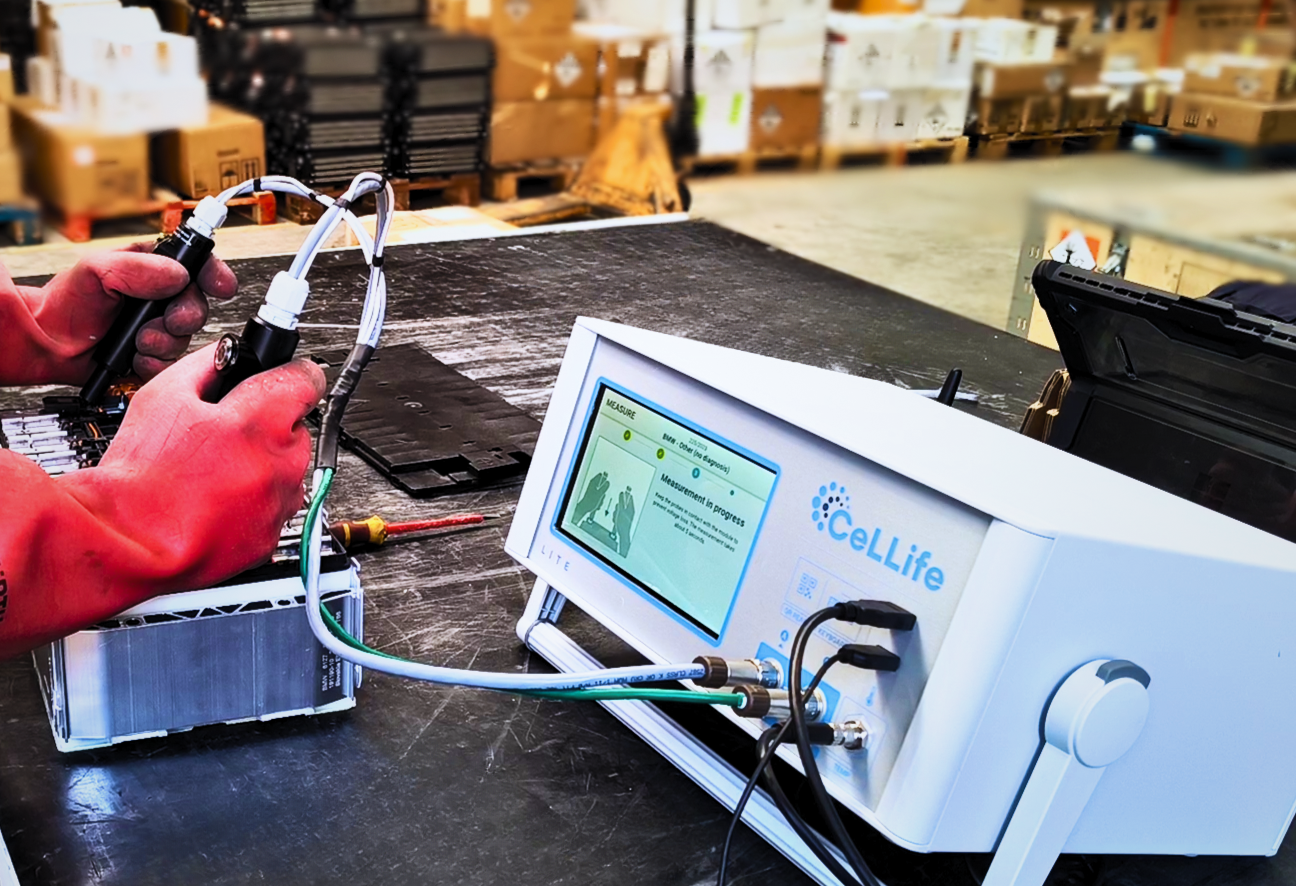

Palmisresíduos adopted CeLLife Lite with Electrical Fingerprint (EFP)™ technology to transform its testing process. With a compact setup and flexible probes, the system captures a module’s diagnostics in just seconds. CeLLife’s AI engine then delivers instant, traceable insights—making EV battery testing faster, more scalable, and more reliable.

The Results: Faster Testing, Greater Efficiency, and Improved Recovery

By deploying CeLLife Lite, Palmiresíduos has:

-

Reduced EV battery testing time from hours/days to seconds

-

Achieved 100% coverage of incoming modules with rapid battery diagnostics

-

Increased throughput to handle growing volumes of EV modules

-

Enhanced recovery of second-life batteries while reducing waste

-

Strengthened sustainability and profitability in the battery recycling chain

“CeLLife Lite has transformed our testing process. What used to take hours now takes just seconds, allowing us to reliably assess every incoming EV module with confidence and efficiency. This solution has removed bottlenecks, improved traceability, and enabled us to maximize recovery while reducing waste.” Nuno Magalhães, CTO at Palmiresíduos

With CeLLife Lite solution, Palmiresíduos has unlocked new levels of speed, reliability, and scalability in EV battery testing. Beyond this success, CeLLife is helping the wider industry reimagine battery module diagnostics, enabling second-life recovery, driving efficiency in battery recycling, and accelerating the transition to a sustainable and circular energy economy.

To stay updated on the latest news from CeLLife, sign up for our monthly newsletter here.